This past week, Tokyo-based Helical Fusion announced a ¥2.3 billion (~$15 million) Series A round. With support from 21 investors, including several large industrial players, the round reflects the expanding diversity of stellarator approaches and a growing ambition in Asia to carve out a more competitive position in the global fusion race.

At the core of Helical Fusion’s plan is an experimentally proven approach: the classical stellarator configuration, directly descended from Japan’s Large Helical Device (LHD). While many fusion startups are pursuing novel reactor concepts, Helical Fusion is opting for a design grounded in decades of experimental validation. The startup, founded less than four years ago, has set an ambitious goal: delivering the world’s first steady-state fusion power plant by 2034.

The Case for Steady-State Reactors

Stellarators confine plasma with magnetic fields generated entirely by external coils, enabling steady-state operation and avoiding the current-driven instabilities that challenge pulsed devices like tokamaks. But achieving effective confinement requires complex 3D coil geometries that have traditionally been expensive and difficult to manufacture. Germany’s Wendelstein 7-X, for example, took nearly a decade to construct and included 50 unique modular coils to generate the main confinement field.

Helical Fusion is opting for a more pragmatic approach. It uses a classical helical configuration, a legacy of Japan’s LHD program, that trades some confinement optimization for simpler, repeatable coil geometry. With modern materials and engineering, Helical Fusion believes it can make this classical configuration commercially viable.

From LHD to Helix Kanata

Helical Fusion’s device uses two large, continuous helical coils wound around the torus. These generate the rotational transform needed to confine the plasma in a steady-state configuration, without any plasma current. The two-fold symmetry simplifies engineering and reduces the number of unique components required for the reactor.

Helical Fusion is upgrading this classic architecture in two key ways:

Using high-temperature superconductors (HTS) that enable higher magnetic field strengths for better plasma confinement.

Incorporating a liquid metal blanket system to breed tritium, extract heat, and provide neutron shielding. Its drainable, modular design would support rapid replacement cycles and extend reactor life.

Classical stellarators tend to suffer from higher particle and energy losses compared to optimized designs like W7-X. By increasing magnetic field strength (and potentially scaling up plasma volume), Helical Fusion believes it can close the performance gap while retaining the engineering simplicity of its helical coil configuration.

To validate its approach, the startup’s development roadmap is structured in two main phases: a scaled-down testbed to de-risk key technologies (Helix Haruka), followed by a full-scale pilot plant aiming for net electric output (Helix Kanata).

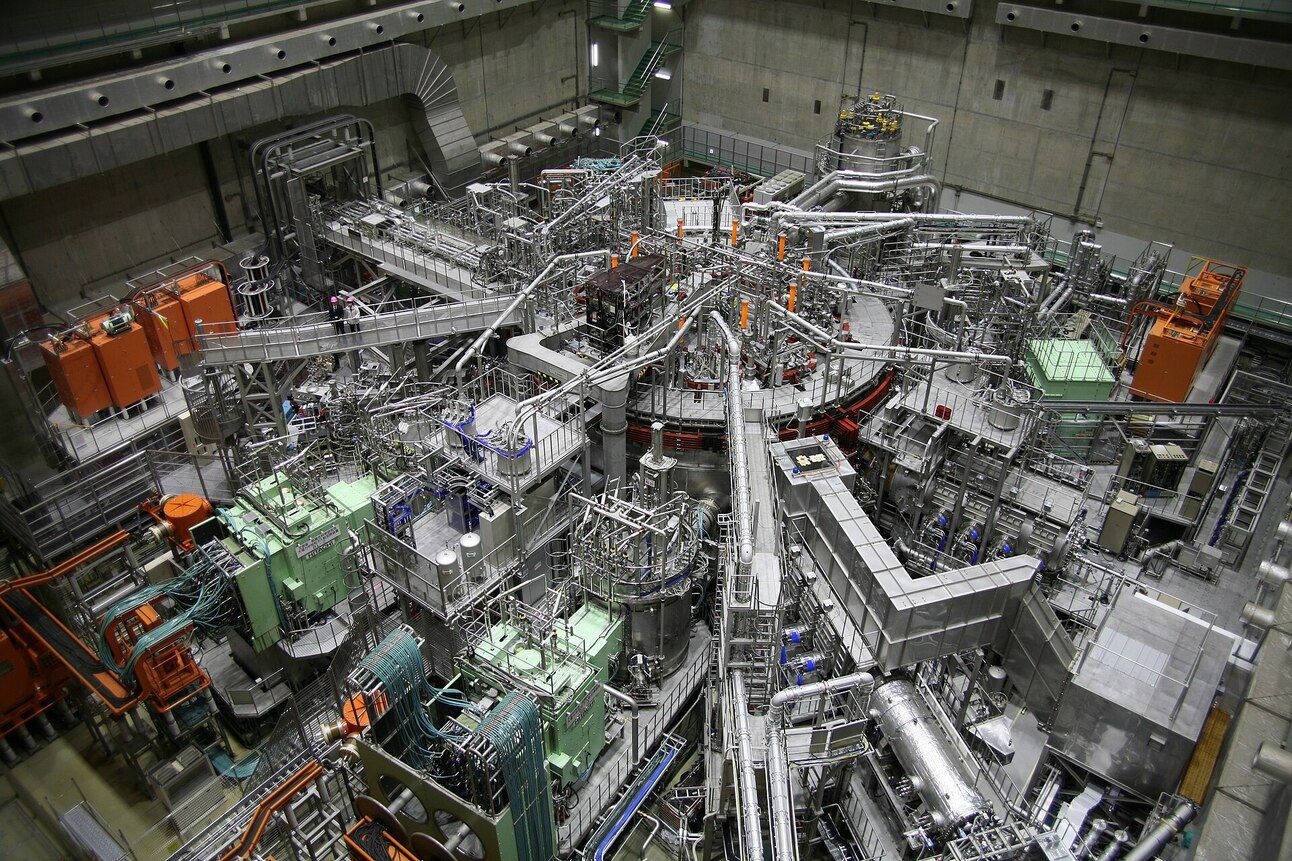

The Large Helical Device (LHD) at Japan’s National Institute for Fusion Science.

Strategic Capital and Policy Alignment

Beyond capital, delivering on this ambitious timeline will require mobilizing expertise across industries, strengthening supply chains, and scaling manufacturing capacity.

To that end, Helical Fusion’s investor base combines institutional capital with strategic corporate partners, including:

Toyoda Gosei – A leading manufacturer of rubber and plastic automotive components, safety systems, and LED technologies.

Okano Valve Mfg. Co. – Supplies and maintains high-performance valves for nuclear power plants and other advanced industrial systems.

Daiwa House – A diversified construction and real estate firm with experience in large-scale infrastructure projects.

In addition to private capital, Helical Fusion has secured public funding through Japan’s Small Business Innovation Research (SBIR) program. The company also plays a key role in shaping national policy as vice chair of J-Fusion, the country’s fusion industry council. This positioning offers a seat at the table in regulatory discussions and could be instrumental in navigating siting, licensing, and future industrial partnerships.

The Open Question

The open question for Helical Fusion is whether a classical stellarator design, even if supported by high-temperature superconductors and a liquid metal blanket, can achieve net power at commercial scale. While other stellarator startups focus on advanced magnetic optimization, Helical Fusion is intentionally trading peak confinement performance for faster execution and lower manufacturing complexity.

Helical Fusion is betting that with modern HTS materials, smart systems integration, and potentially a larger plasma volume, it can narrow the performance gap between classical and quasi-symmetric stellarator designs. If successful, it could be the first to bring a steady-state fusion plant to the grid, offering a more cost-effective and scalable path to commercial fusion.