A study published last week in the journal Nuclear Fusion proposes a new framework for estimating fusion blanket lifetimes under pulsed operational conditions.

Blankets are critical (and highly vulnerable) reactor components. They must breed tritium, extract heat, and withstand extreme neutron flux and thermal cycling. Failures can trigger complex maintenance, hurting reactor uptime. In severe cases, they can also create safety risks.

Contextually, this work builds on decades of research into blanket material durability and fatigue. Previous studies, such as ITER’s Test Blanket Module campaigns and the EU’s DEMO blanket analyses, have focused on thermal-mechanical fatigue, creep, and neutron-induced damage under continuous or near-steady state operational conditions.

While older efforts established baseline material behavior and lifetime predictions, they often relied on deterministic approaches, providing single-point estimates rather than probabilistic distributions. This new framework takes things a step further by modeling pulsed operational loads and including statistical uncertainty, letting engineers look at failure probabilities instead of just a single lifetime and better capture the natural variability in materials and reactor conditions.

Framework Overview

The model combines three key elements:

Physics-based material damage modeling: Captures mechanisms like swelling and neutron embrittlement under operational stress.

Characterization of pulsed operational loads: Quantifies the thermal and mechanical cycling imposed by plasma pulses.

Particle-filtering Bayesian Monte Carlo: Continuously updates predictions as new experimental or operational data become available, refining the probability distribution of failure in near real-time.

The approach, borrowing from aerospace and industrial reliability engineering, allows engineers to move beyond conservative guesswork and make evidence-based comparisons between blanket designs.

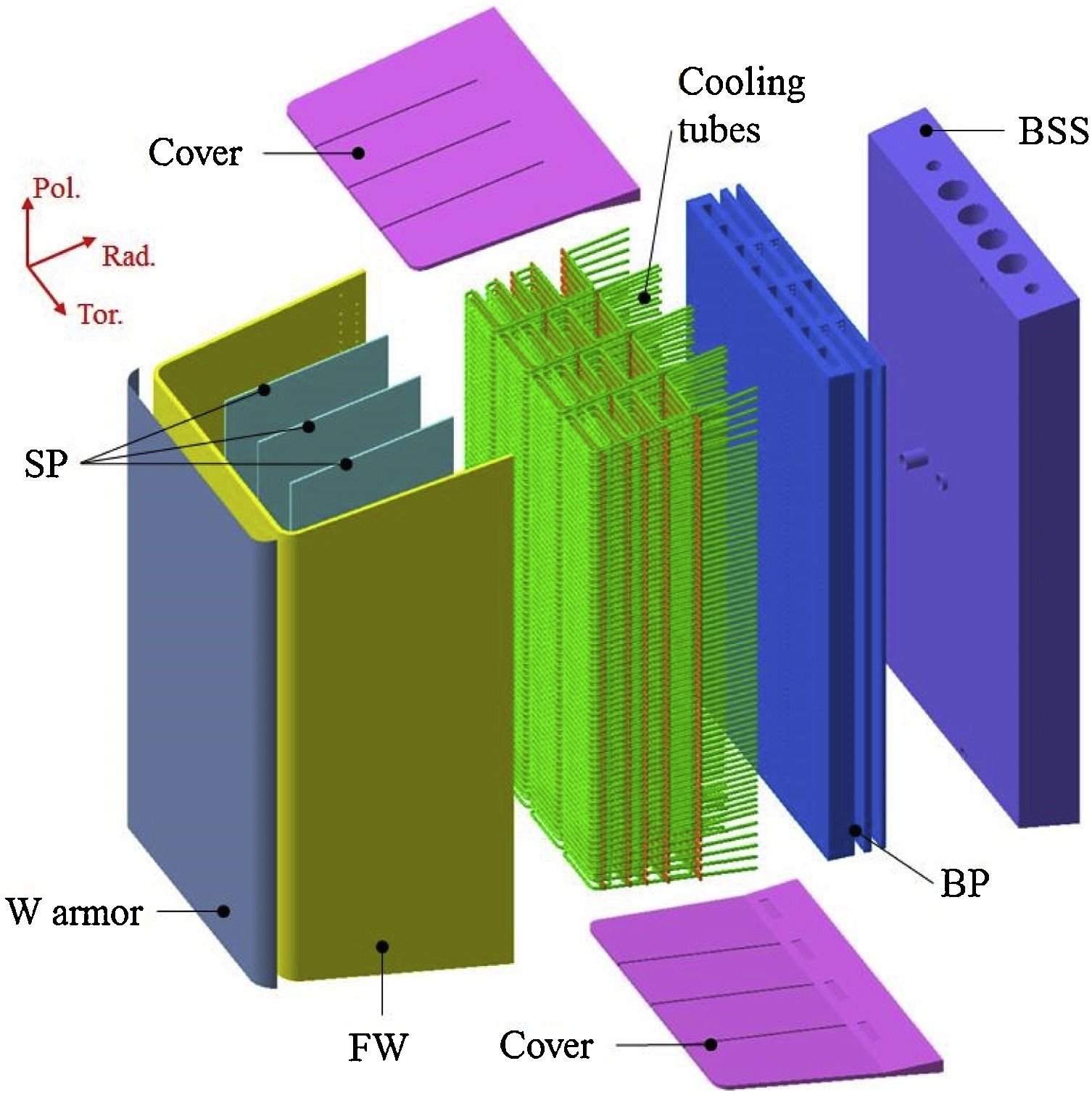

Application to CFETR’s WCCB Blanket

When applied to the Water-Cooled Ceramic Breeder (WCCB) blanket of the Chinese Fusion Engineering Testing Reactor (CFETR), the model predicted a mean time between failures (MTBF) of ~21.7 years for the first wall, well above the ~11-year benchmark often cited for demonstration reactors. At face value, this suggests that the WCCB design could be reliable in a commercial setting.

However, several factors temper this optimism:

Creep-fatigue interactions: The model currently assumes continuous operation. In reality, repeated plasma pulses produce thermal cycling, accelerating microstructural damage and reducing the actual lifetime. The researchers note that incorporating these effects could meaningfully lower the MTBF.

Limited validation: The framework has so far been applied only to CFETR’s WCCB blanket. Other blanket designs, such as helium-cooled lithium-lead blankets, may respond differently under similar conditions.

Simplified neutron damage modeling: While physics-based, the model relies on degradation data that may not fully capture long-term neutron embrittlement or transmutation effects.

Material heterogeneity: The approach assumes well-characterized and statistically independent material properties. Local defects, weld inconsistencies, or unexpected impurities could concentrate stress and lead to earlier failures.

System-level interactions: Blanket failures interact with coolant loops, magnet systems, and diagnostics in ways not captured by the model. These interactions could affect both reliability and safety.

In short, the 21.7-year MTBF should be viewed as an optimistic preliminary finding rather than a definitive prediction.

Implications for Industry

Despite their limitations, studies like this one are essential for the fusion industry to better assess and manage blanket reliability:

Informed design choices: By providing a probabilistic estimate of component lifetimes, the framework allows R&D teams to compare materials and designs quantitatively, prioritize investments, and reduce risk.

Maintenance optimization: Time-dependent failure rates can inform predictive maintenance schedules, allowing operators to plan replacements or inspections before failure probabilities spike.

Operational and financial planning: Blanket failures would be among the most expensive and disruptive events in reactor operations. Probabilistic forecasts help investors, regulators, and operators understand risk, improving confidence in plant availability and economics.

As fusion reactors move from lab-scale experiments to prototype power plants, these predictive, probabilistic models become essential. Ongoing efforts to include high-temperature creep-fatigue effects and system-level interactions should further improve their accuracy.