High magnetic fields are the core enabler of tokamak performance. They raise plasma pressure and improve confinement, letting reactors hit fusion conditions at much smaller scale. Historically, achieving those fields demanded massive, cost-prohibitive superconducting systems. High temperature superconducting (HTS) materials like REBCO have upended that constraint.

In 2021, MIT and Commonwealth Fusion Systems (CFS) demonstrated a 20-tesla HTS magnet, proving that REBCO coils could reach the field strengths needed for a net-energy tokamak. Tokamak Energy likewise set its own single-magnet records (exceeding 22 T in 2019 and 26 T in 2020) in laboratory settings.

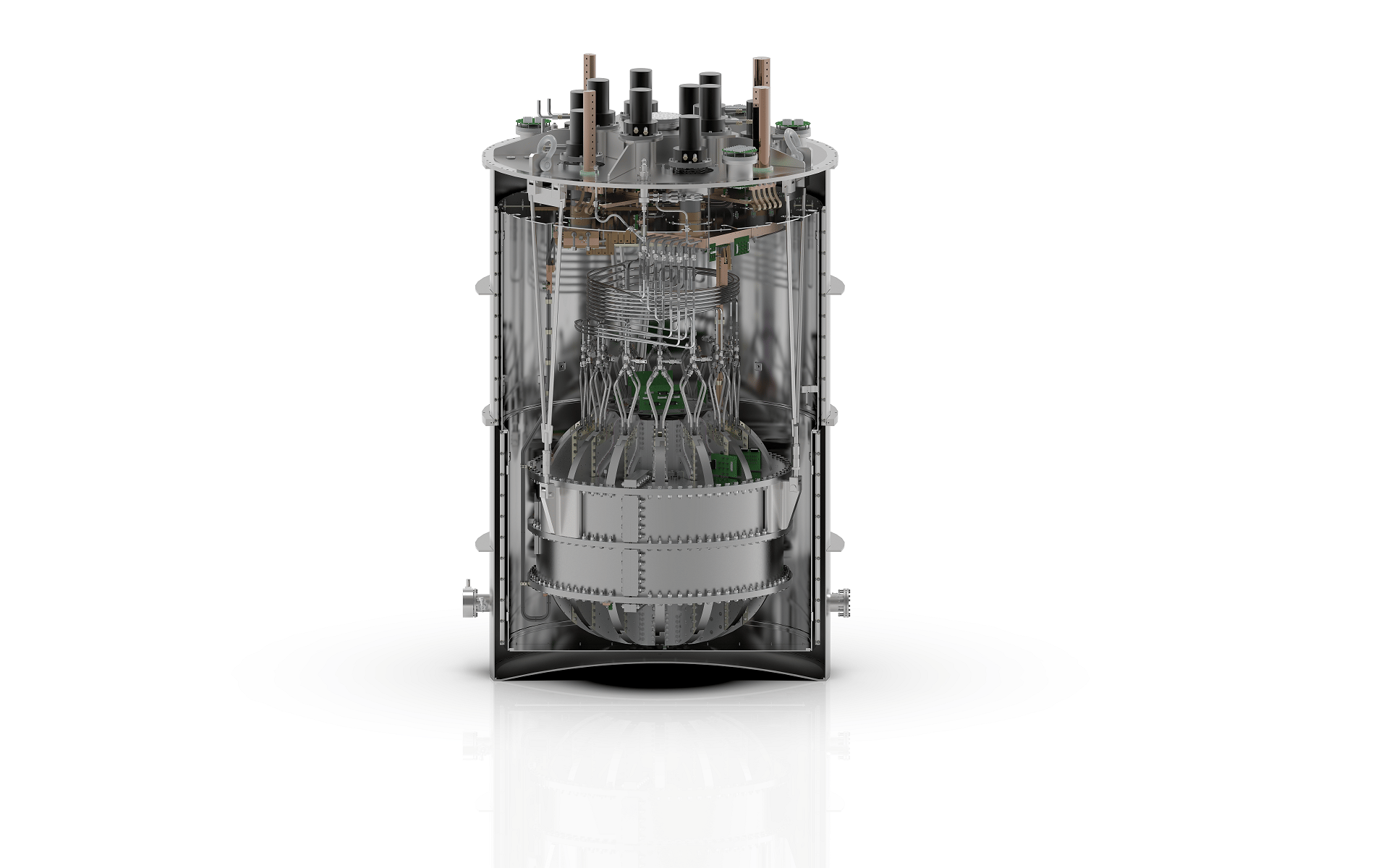

However, a fusion plant requires an array of magnets operating together under combined loads. Tokamak Energy’s Demo4 testbed addressed this next engineering step: it’s the first platform to test a complete HTS magnet cage under fusion-relevant conditions. The system carried seven million ampere-turns through its central column and delivered fields of 11.8 tesla.

The 14 TF (toroidal field) coils plus 2 PF (poloidal field) coils in Demo4 allowed engineers to study interactions like magnetic fringe fields and structural forces that isolated tests cannot replicate. The recent success of Demo4 confirms that HTS magnets perform as expected at system scale, maintaining high fields and current densities with manageable cooling.

CFS is following a similar path: in late 2025, it completed testing of its first production HTS coils for the SPARC tokamak, with U.S. Department of Energy experts verifying the magnets met all performance specs.

Scaling up magnet manufacturing

Achieving performance in one magnet is only half the battle; the other is producing them reliably and at scale. To support this goal, Tokamak Energy launched TE Magnetics in 2024 as a dedicated business unit to commercialize its HTS technology for both fusion and adjacent markets.

The company is rapidly scaling its manufacturing capabilities, in part through international partnerships. In 2025, Tokamak Energy and Japan’s Furukawa Electric (a major HTS tape supplier) agreed to establish a joint facility in Japan to mass-produce fusion-grade magnets. This followed Furukawa’s strategic investment in Tokamak Energy and a UK-Japan government fusion collaboration, underlining the global supply chain being built around HTS materials.

Similarly, Tokamak Energy signed an MoU with General Atomics, leveraging GA’s experience in large-scale superconducting magnets (e.g. ITER’s central solenoid) to help manufacture HTS coils for future reactors. These partnerships could help ensure that when prototype reactors are ready, the high-field magnets can be produced at scale, with the quality control and cost-efficiency that power plants will require.

Other startups in the sector are taking a similarly collaborative approach. Commonwealth Fusion Systems, after perfecting its own magnet design, is now licensing its HTS cable technology to other fusion startups. It’s a win-win strategy: CFS can grow the addressable market for its own magnet platform while pushing competing fusion concepts forward at a fraction of the cost.

Tokamak Energy’s rendering of its Demo4 superconducting magnet system.

Closing thoughts

Demo4 proved that a full spherical-tokamak magnet assembly can hit reactor-grade fields with stable performance. That lends credibility to Tokamak Energy’s long-standing claim that its high-field, compact devices can scale to power-plant conditions.

With magnet technology largely proven, the focus can shift to other integration challenges: from sustaining stable plasmas and managing heat exhaust, to developing neutron-resistant materials. There are still plenty of engineering hurdles ahead, but Tokamak Energy’s latest milestone makes its 2030s power-delivery target look increasingly plausible.